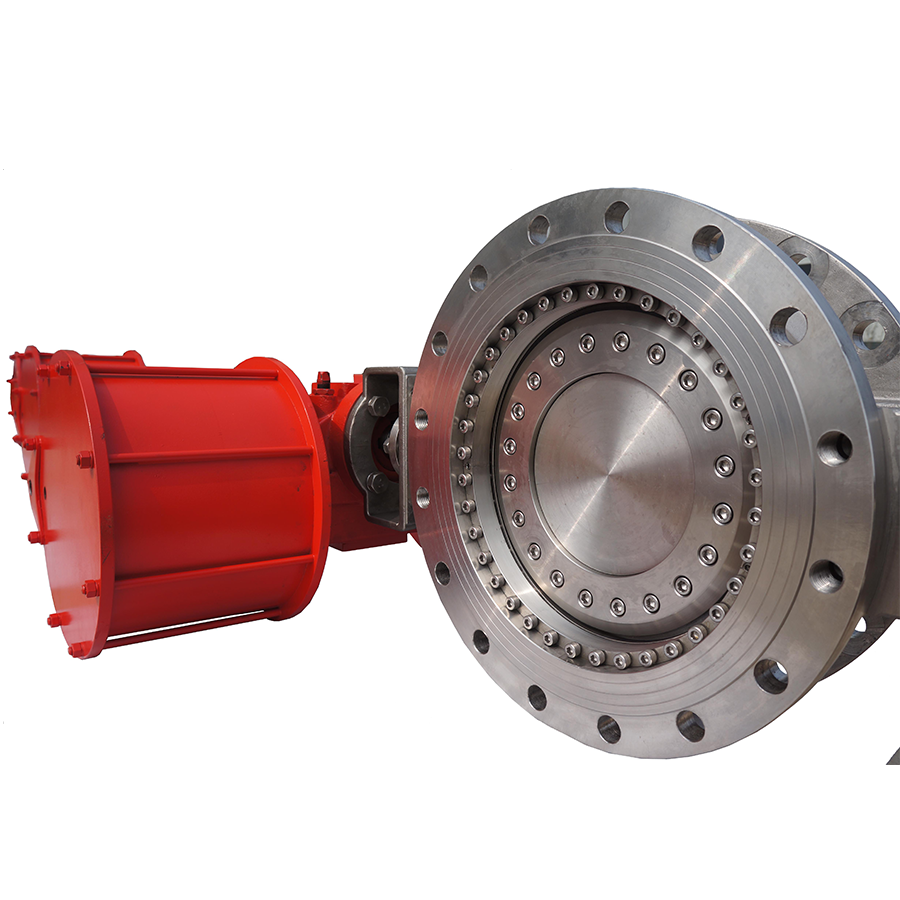

butterfly valve

| Size | 2” up to 88“ (DN 50 up to DN 2200) |

|---|---|

| Pressure rating | CLASS 150 to 900 CLASS / PN10 to PN150 |

| Materials : | Ductile iron / Cast iron , Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Low alloy steel , Nickel Alloys, Nickel Aluminium Bronze, Hastelloy, Inconel, Monel, Nickel, Titanium, Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay |

| Design Standard | API 609 / ANSI B16.34 / BS 5155 / BS 5353 / EN593 / JIS B2071 / DIN 3354 / MSS SP 67 / DIN 3354 / AWWA |

| Test (Inspection) Standard | API 598 / API 6D / ISO 5208 / EN 12266-1 |

| End Connection | Wafer type , Lug Type , Flange Type |

| Seat Material | EPDM / NBR / PTFE / NYLON / Metal to Metal seat |

| Operation | Lever, Gear, Actuator (Pneumatic, Hydraulic, and Electric Motorised) |

Butterfly Valves are available in below type

- Double Offset

- Triple Offset

- Concentric

- Extended Stem

Cryogenic Service

- Butterfly Valve can be designed in a special version suitable for cryogenic service. In this case, all the materials and technical features are designed to withstand minimum design temperature required by the Customer. If required by the customer, specific Cryogenic Tests are performed to verify the behaviour of valves sealing capability, emissions vs the ambient.