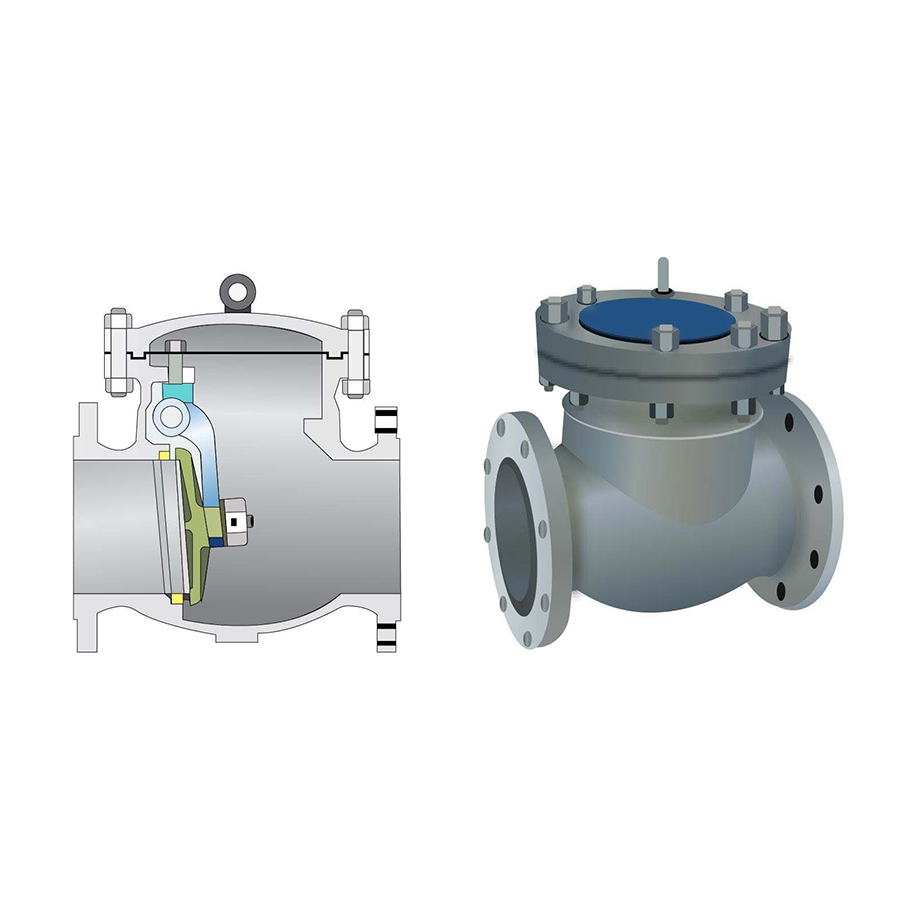

check valve

| Size | 2” up to 56“ (DN 15 up to DN 1400) |

|---|---|

| Pressure rating | ASME 150 Class to 2500 Class / PN10–PN420 |

| Materials : | Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Low alloy steel , Nickel Alloys, Nickel Aluminium Bronze, Hastelloy, Inconel, Monel, Nickel, Titanium, Alloy & Carbon Steel with Internal Corrosion Resistant Alloy (CRA) Overlay |

Applicable standards

- Design& Manufacture: BS 1868 / ASME B16.34 / API 6D

- Face to Face: ASME B16.10 / API 6D / EN 558.1 / DIN 3202

- Flange Ends: ASME B16.5 / ASME B14.47 / EN 1092-1

- Butt-weld Ends: ASME B16.25 / EN 12627

- Inspection and test: API 598 / API 6D / EN 12266 / ISO 5208 / ISO15848-1&2 / BS6364

Construction Details

- Bolted Cover / Pressure Seal Bonnet, Lift Check Type, Swing Check, Piston Check, Tilting Disc, Non – Slam Check

End Connection

- Flanged (RF,FF,RTJ) , Hub End, Butt-Weld

Check Valves are Available in Below Types

- Swing Type Bolted Bonnet

- Piston type check valves

- Non-Slam Check Valves

- Tilting Disc type

- Nozzle type

Cryogenic Service

- Check Valve can be designed in a special version suitable for cryogenic service. In this case, all the materials and technical features are designed to withstand minimum design temperature required by the Customer, down to Cryogenic -196°C. If required by the customer, specific Cryogenic Tests are performed to verify the behaviour of valves sealing capability, emissions vs the ambient.