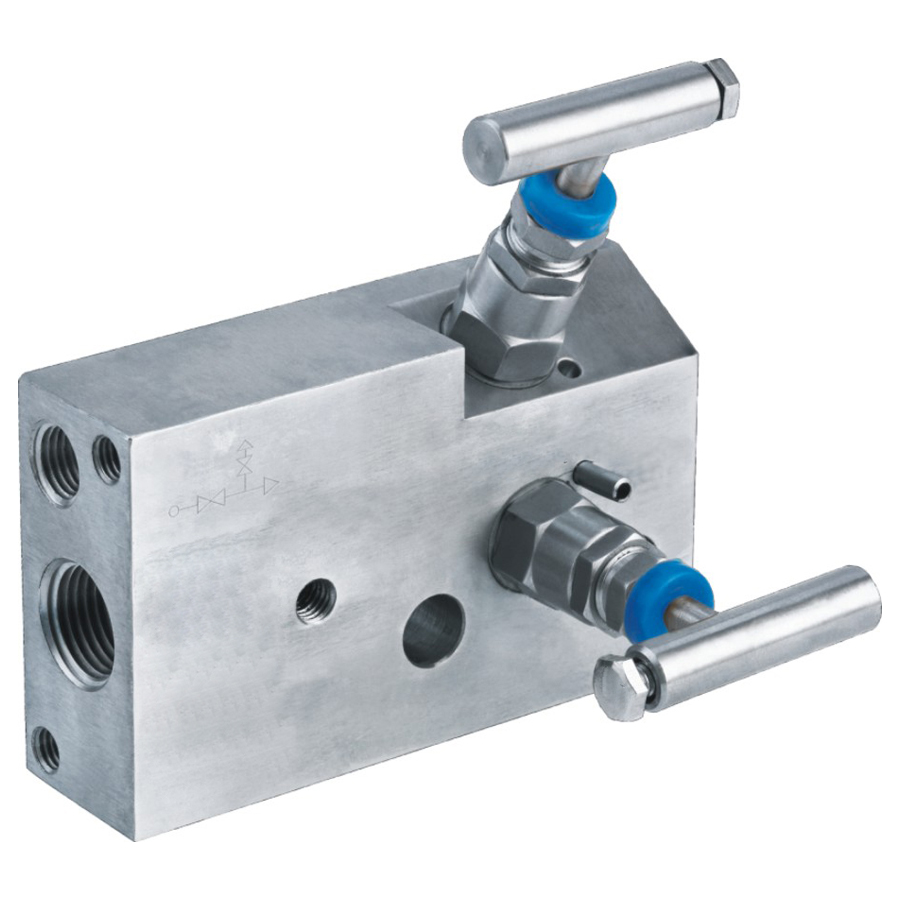

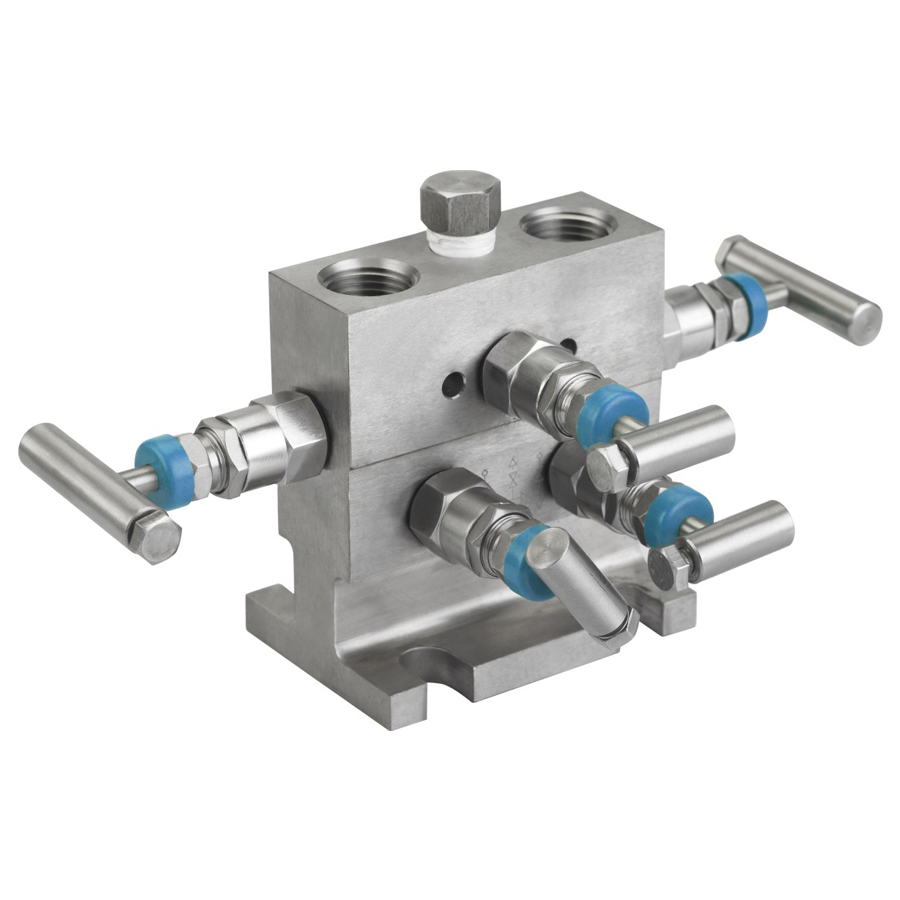

two valve manifolds

The valve manifold pipe to pipe design for separate mounting Connecting system impulse lines and transmitters, having simple two valve configuration which allows for easy block, bleed and calibration of a static pressure transmitter of gauge.

- 316 stainless steel body

- Non-rotatingng Vee tip

- Graphoil packing material is available (Optional) for high temperatures 1000 F at 6000 psi

- Design standard: ANSI B16.34

- Valve Design standard: ANSI B16-Class 2500

- Sour gas services confirm to NACE MR-01-75

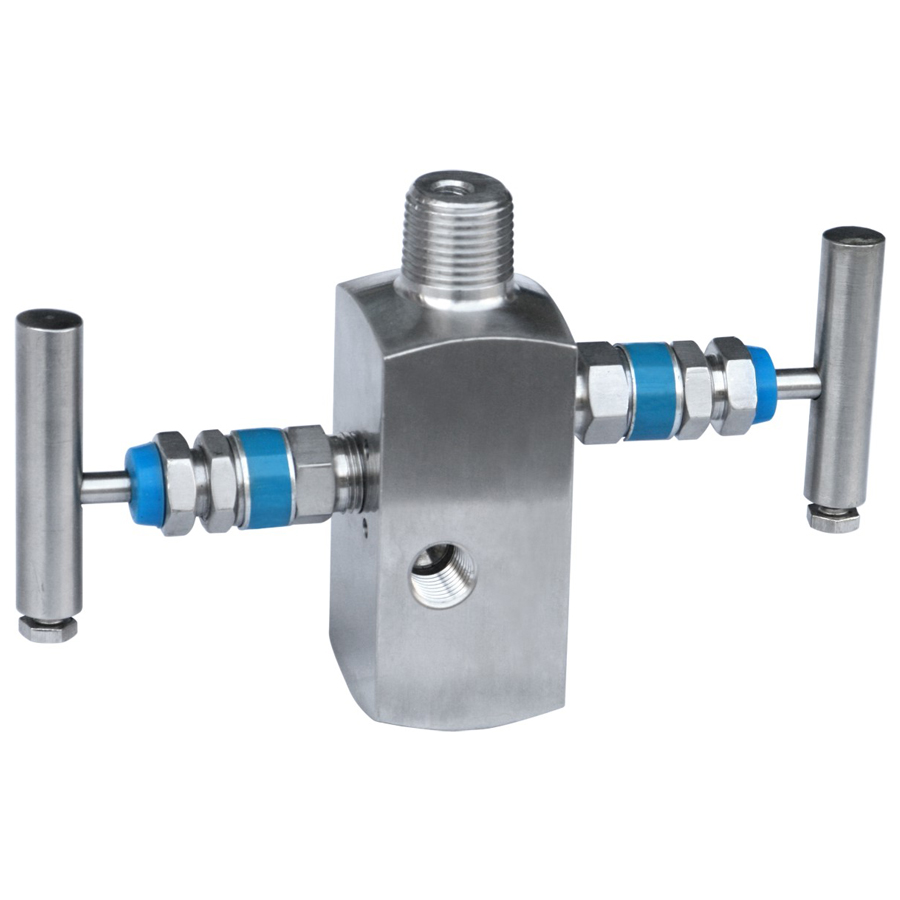

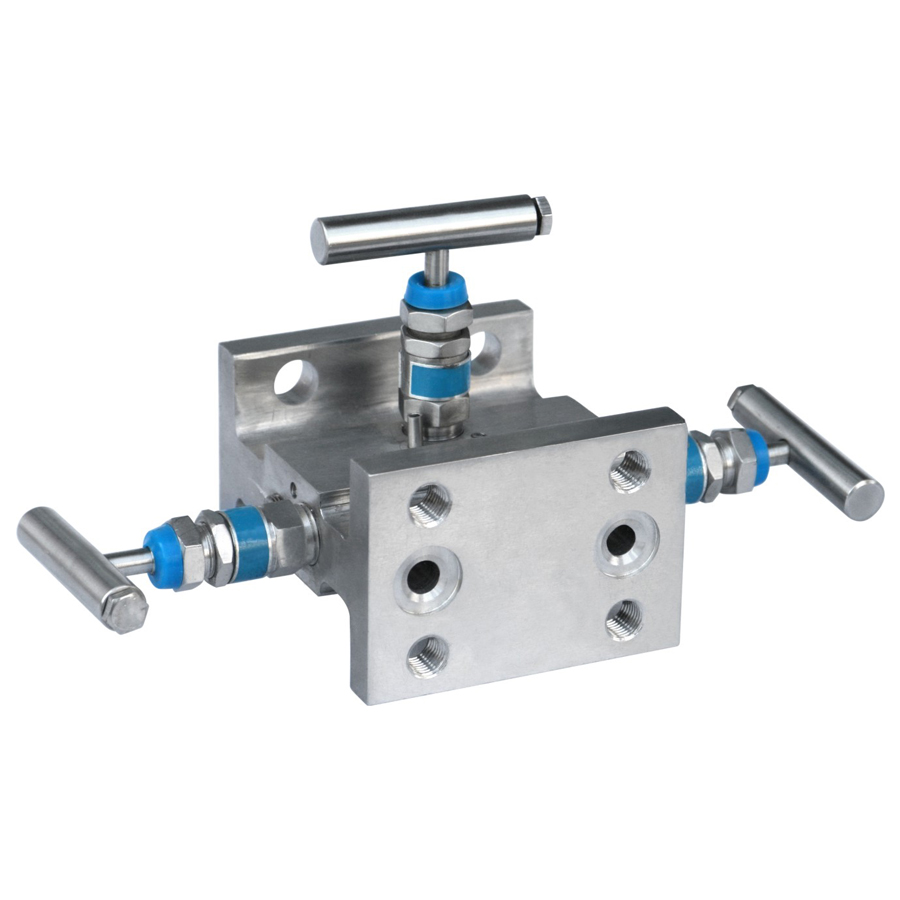

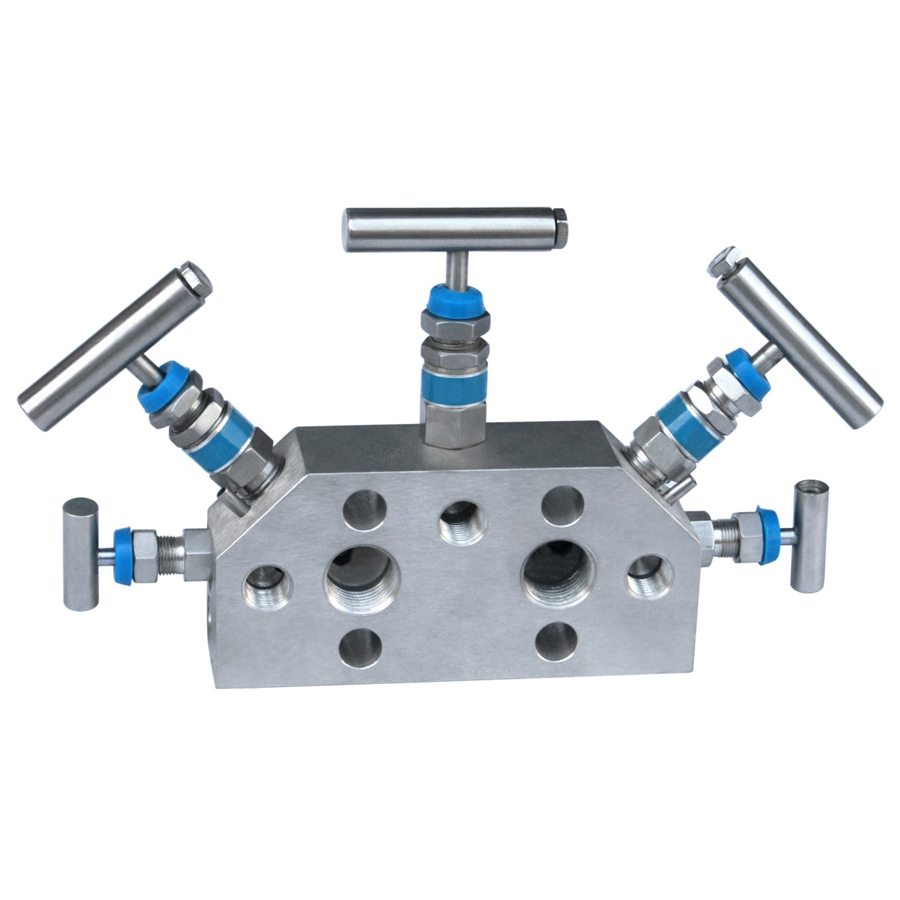

three valve manifolds

- Manufacture in accordance with MSS - SP - 99. The valves are used with differential pressure measuring Instruments.

- Materials: SS 316, SS 316 L, Carbon steel, Duplex Steel, Super Duplex steel, Monel, Inconel, Hastelloy.

- Materials in accordance with NACE MR 0175 are also available on request.

- Standard process connection: 1/2" NPT, G1/2Standard instrument connections: 1/2" NPT, G1/2 or flanged

- Maximum working pressure: Up to 690 bar/10000 PSI at 100°C.

- Gland packing: PTFE / Graphite Remote mounting & Direct mounting options are there with various models and types.

- Standard construction is integral metal seat, soft seat valves are available on request.

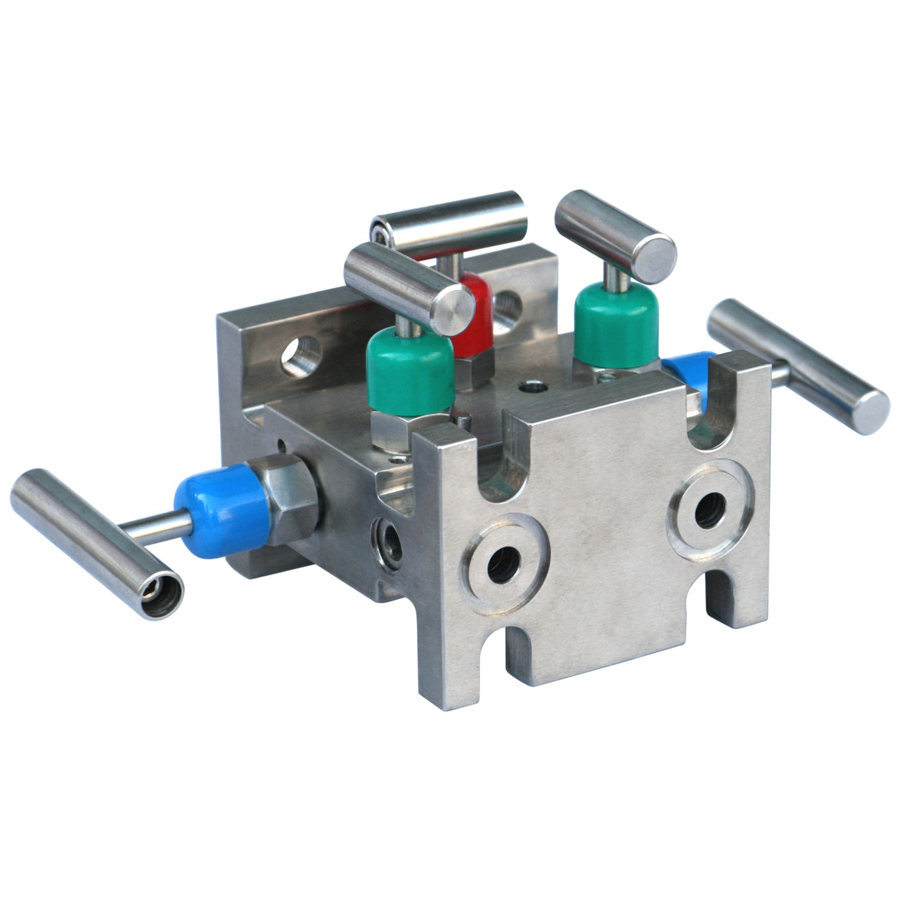

five valve manifolds

- Manufacture in accordance with MSS - SP - 99. The valves are used with differential pressure measuring Instruments.

- Materials: SS 316, SS 316 L, Carbon steel, Duplex Steel, Super Duplex steel, Monel, Inconel, Hastelloy.

- Materials in accordance with NACE MR 0175 are also available on request.

- Standard process connection: 1/2" NPT, G1/2Standard instrument connections: 1/2" NPT, G1/2 or flanged

- Maximum working pressure: Up to 690 bar/10000 PSI at 100°C.

- Gland packing: PTFE / Graphite Remote mounting & Direct mounting options are there with various models and types.

- Standard construction is integral metal seat, soft seat valves are available on request.